At LKHE(M), we provide customised flexible links that

- Absorbs vibrations caused by operations and movements inside machines

- Protects against movements and expansions in machines and equipment

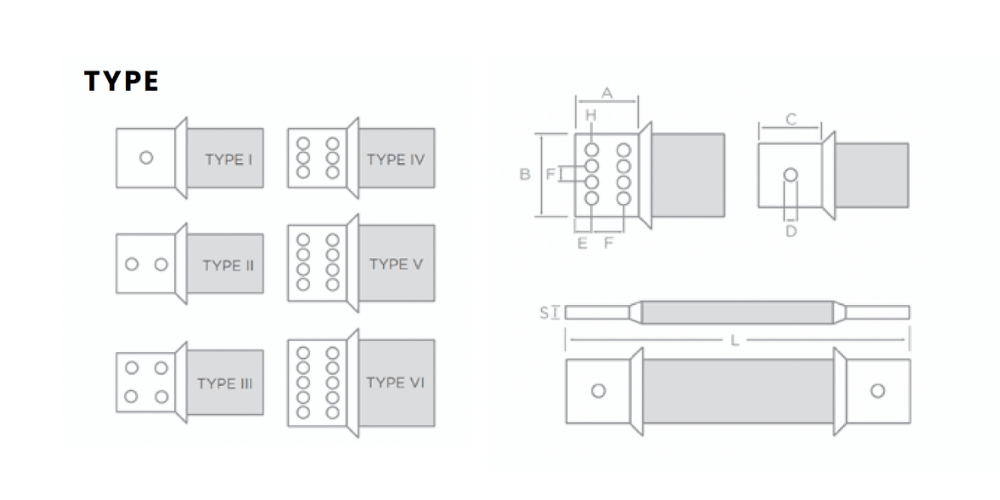

Standard flexible dimensions: L = 300 F = 50 E = 25

While enquiring please specify

Besides flexibles can also be fabricated as per your design, size and specifications.

Highly flexible connectors

Standard flexibles

Advantage of solderless pressing process

Standard manufactured connectors

Flexible connectors

Laminated connectors

Area of applications

Note: These kind of connectors have to realise movement inside machines and switch gears. We have different methods of production, to manufacture suitable connectors for the variable applications.

Hence, we are able to provide connectors in

Take a look at the concerns previously raised by others and find the answer you need.

Reach out to us to enquire about our products and services, seek technical support, and assist with complaints.