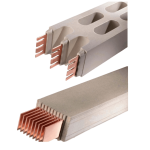

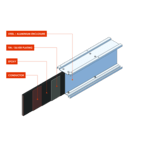

- Sandwich construction

- Reliable and efficient electrical distribution system with superior performance.

- Safe and robust power distribution system

- High electrical efficiency, low voltage drop, high mechanical strength

T Line I Busbar Trunking System

Exclusively distributed by LKHE(M)

the safety of YOUR system

conductivity

copper conductor

insulation

Busbar

Trunking

System

Busbar

Trunking

System

Busbar

Trunking

System

Busbar

Trunking

System

Busbar

Trunking

System

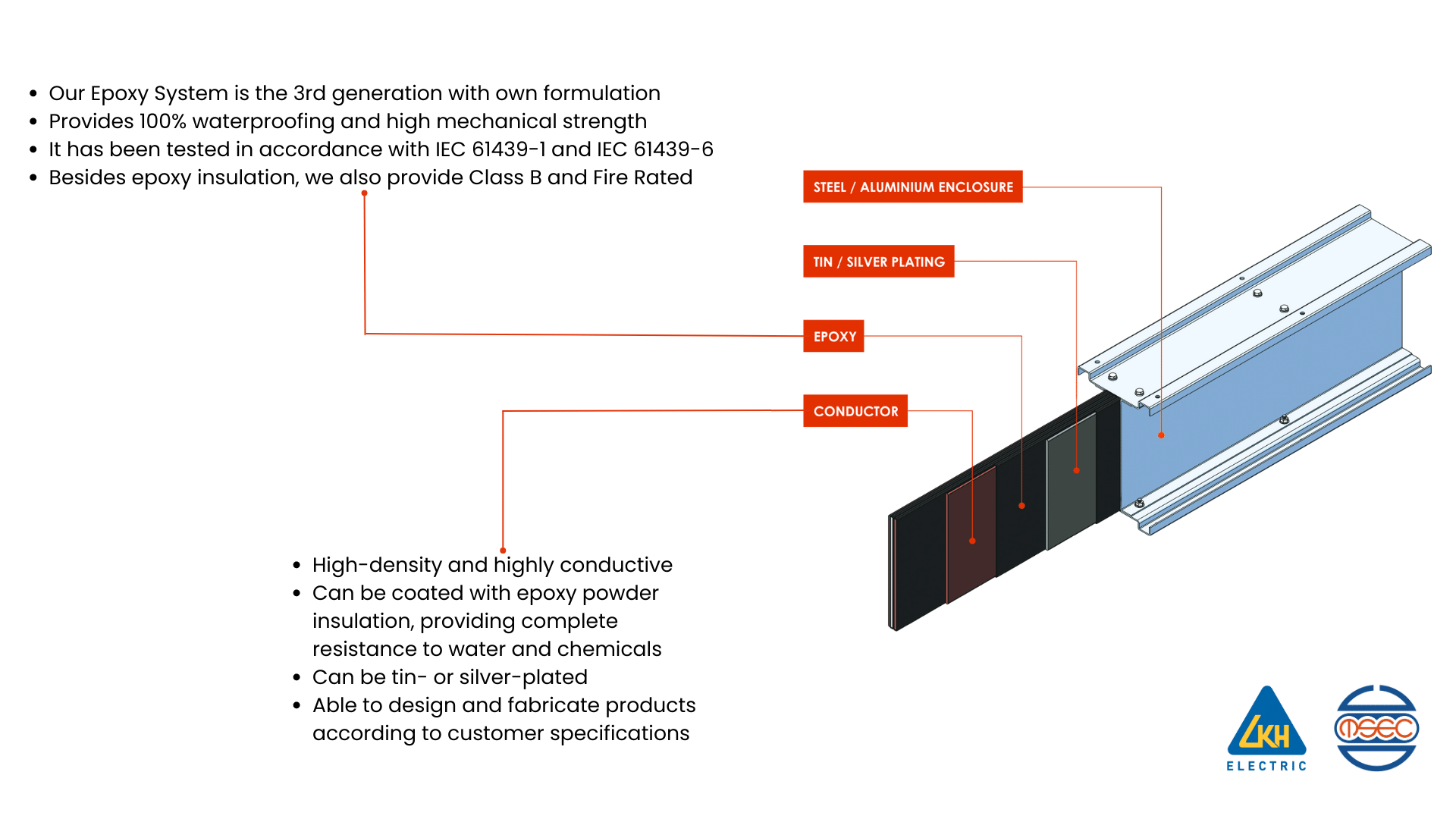

Our Epoxy System is the 3rd generation with own formulation. The class H-180°C standard epoxy coating provides 100% waterproofing and high mechanical strength. It has been tested in accordance with IEC 61439-1 and IEC 61439-6.

Advantages of using epoxy coating as insulations:

- Designed to withstand glitch and spikes in electrical system

- Designed to cater for expansion and contraction during peak and off-peak hours

- Capable of withstanding heat shock

- High reliability under static conditions

- High mechanical strength against impact

- High thermal conductivity

- Water and chemical resistant

Other Insulation Types

Besides epoxy insulation, we also provide other classes of insulation as below:

- Class B – It consists of two layers of Mylar (Polyester Film) which resists temperature up to 130°C.

- Fire Rated – It consists of 1 layer of Mylar (Polyester Film) and 2 layers of Mica (mineral silicate sheet) which resist temperature up to 900°C.

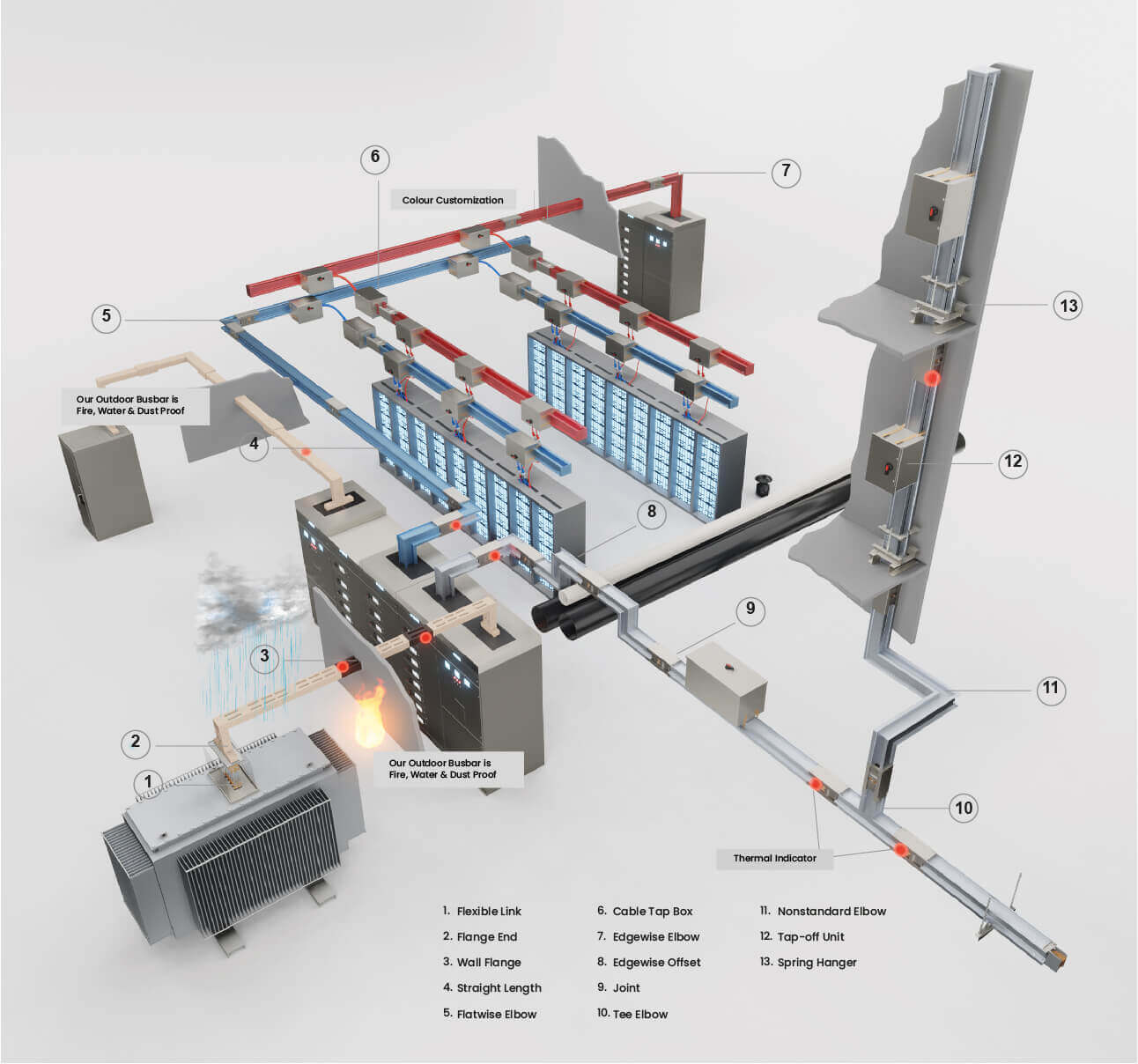

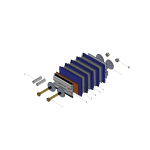

In order to overcome extreme rugged conditions at site, the new Busbar Trunking System joint has been designed precisely and manufactured using the highest quality of materials to minimize all possible problems and enhance system performance.

This special design provides outstanding features as follows:

- Incorporates a 5mm thermal expansion and movement at every point.

- Allow ±15mm of lateral adjustment (total 30mm) to correct site measurement inaccuracy.

- Able to tilt an angle of ±5° (total 10° along a single axis).

- Bolt and nuts can be stainless steel, galvanized or chromed black high tensile steel.

- Degree of protection of IP40-IP66.

- Easy installation and removal at any joint in a run without disturbing the two adjacent Busbar Trunking System sections.

- Water/chemical resistance BMC insulation plates.

All our products are high density and conductivity. Copper conductor has minimum purity of 99.95% with conductivity of >100% IACS while aluminium has minimum purity of 99.7% with conductivity>61% IACS. It is fabricated through a sophisticated thermal compression process which involves application of tremendous heat under high pressure. It can be tinned or silver-plated with epoxy powder coated as insulation giving 100% water and chemical resistance. Optional specifications can be designed and fabricated to customer requirement.

Advantages of using our conductor:

- High electrical conductivity

- Low impurity

- Excellent fatigue resistance

- High thermal conductivity

- High mechanical strength

- Outstanding corrosion resistant

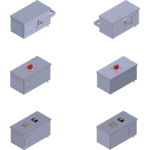

Tap-off unit with moulded case circuit breaker (MCCB) or fused-switch breakers of various current ratings are available to cater for most installations. Maximum 5 tap-off units per side can be installed, total 10 nos per length of 3m busbar subject to the size of MCCBs.

- All tap-off unit are designed with interlocking safety features to prevent removal when tap-off unit in ‘On’ position.

- When tap-off unit cover is open, automatically, MCCB cannot be turned ‘On’

| Description | Specifications & Standards |

|---|---|

| Model | T Line I |

| Type | Sandwich |

| Compliance Standard | Kema Keur BS 6387 IEC 61439-6 |

| Seismic Level | Zone 4 |

| Current Rating | CU: 800A to 6300A AL: 630A to 6300A |

| Rated Insulation Voltage (Ui) | 1000V |

| Rated Frequency (Fn) | 50Hz/60Hz |

| Conductor Material | Copper/Aluminum |

| Operation Temperate | Avg: 35deg C, Max: 55deg C |

| System Configuration* | 3P3W 3P3W+50%E 3P4W(100%N)+50%E 3P4W(100%N)+100%E 3P4W(200%N) 3P4W(200%N)+50%E |

| Rated Short Circuit Current for 1sec | 40kA - 150kA |

| IP Rating | IP40 / IP42 / IP54 / IP55 IP65 / IP66 |

| Insulation Material | Type 1: Epoxy - Class H - 180degC Type 2: 2 layers of Mylar (Polyester Film) - Class H - 130degC Type 3: 1 layer of Mylar (Polyester Film) & 2 Layers of Mica - Fire Rated - 900degC |

| Housing | 4 pieces of housing (Steel Housing) |

| Insulation Class | 180deg C - Class H 130deg C - Class B |

| Fire Rated | 950deg C, 3 hours (BS6387C) |

T Line I Busbar Trunking System Catalogue

Manufacturer of Power Distribution System since 1980s

- The only brand that conducts factory routine test in Singapore

- Provide local technical and replacement/repair support with the shortest lead time

- Type tested and certified to IEC 61439-6 standard

- Quality assured with 3rd party (KEMA) surveillance

Strong after-sales services

Support you with individualized consultation and tailor our solution to suit your needs and in compliance with the relevant standards

- Be personally accountable for our desired results. We will take responsibility for every aspect of our products and services.

- Be proactive. We stay ahead of the curve with customers, anticipating problems and acting in advance to solve them.

Our Certifications

- Product and production location will be under surveillance of KEMA

- Ensure product produced identical to those originally tested

- Complete IEC61439-6 type tests

- The certification mark can be applied to the label as per specified duration of the certification

- Certification Validity will be published on KEMA website

- Resistance to flame progagation

- Fire resistance in building penetration

- Resistance of insulating materials to abnormal heat & fire

Register your interest for a product sharing session!

Related Products

Help Functions

Take a look at the concerns previously raised by others and find the answer you need.

Reach out to us to enquire about our products and services, seek technical support, and assist with complaints.